Humanoid Robots and Robotics: Revolutionizing Industries in America

Humanoid Robots and Robotics: Revolutionizing Industries in America

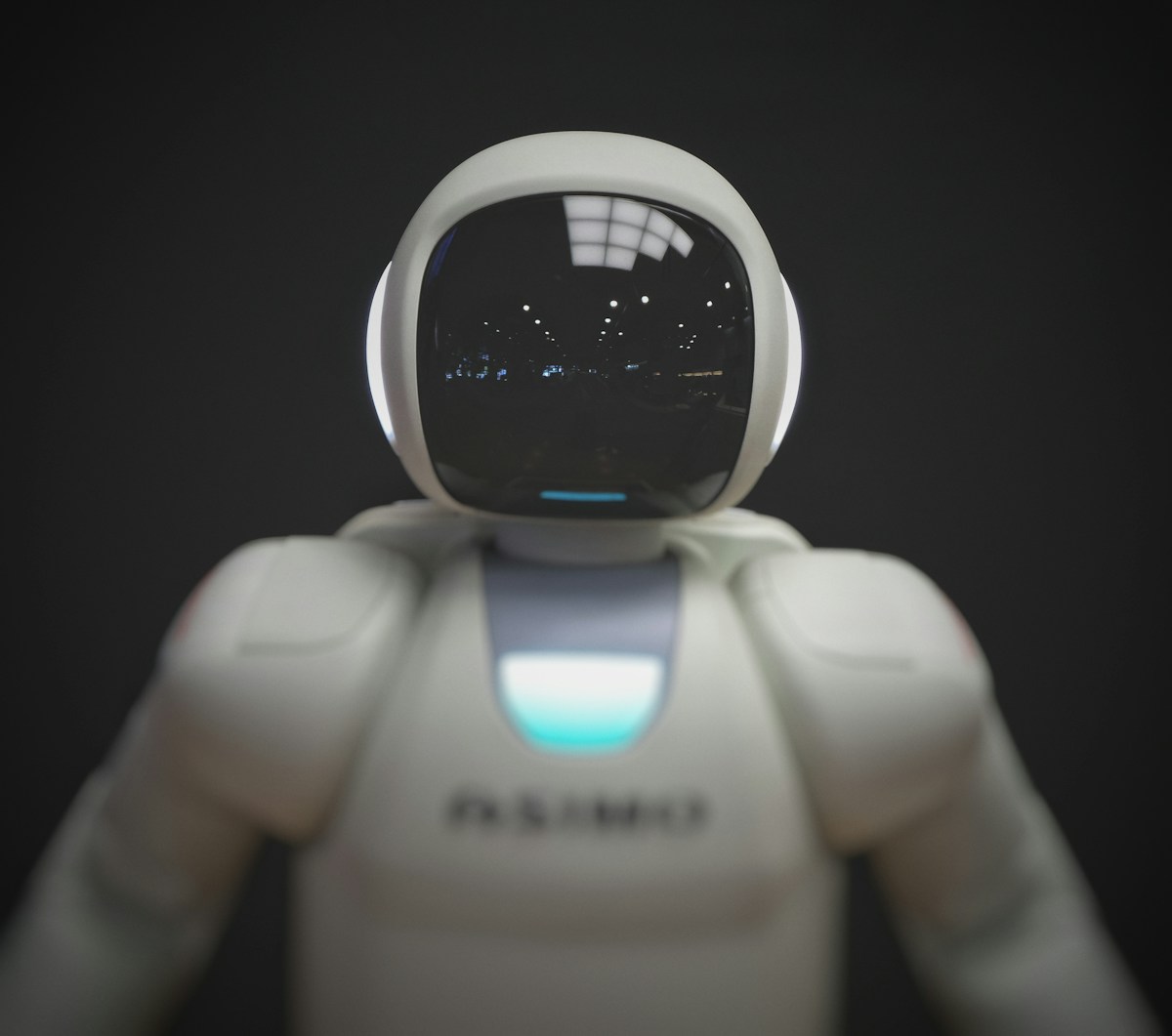

Picture a factory floor where robots don't just assemble parts—they walk, think, and collaborate alongside human workers as genuine teammates. This isn't science fiction anymore. From Tesla's Optimus assisting in automotive plants to Boston Dynamics' Atlas performing backflips, humanoid robots are transforming American industries at an unprecedented pace. As manufacturers face labor shortages and rising costs, these human-shaped machines are emerging as the solution that could reshape everything from warehouses to healthcare facilities across the United States.

What Are Humanoid Robots?

Humanoid robots are sophisticated machines designed to resemble and move like humans, featuring a torso, head, two arms, and two legs. Unlike traditional industrial robots confined to single repetitive tasks, humanoids possess the adaptability to navigate human-designed environments and use tools originally created for people.

The journey began in the 1980s when pioneers like Carver Mead developed the first silicon-based robotic neurons. Today, American companies lead the charge with groundbreaking innovations. Boston Dynamics showcases unparalleled agility with its Electric Atlas performing dynamic movements, while Agility Robotics deploys its Digit robots in Amazon warehouses for autonomous package handling.

The Human-Like Advantage

What makes humanoid robots particularly valuable for American businesses is their anthropomorphic design. They can climb stairs, operate door handles, and work at standard-height workstations—capabilities that allow them to integrate seamlessly into existing infrastructure without costly facility modifications. This design philosophy addresses a critical pain point: retrofitting brownfield sites would cost billions, but humanoids work within environments already optimized for human workers.

How Humanoid Robots Work: Technology Behind the Innovation

Modern humanoid robots combine three revolutionary technologies that enable their human-like capabilities:

Advanced Sensor Systems

Humanoids perceive their environment through sophisticated sensor arrays including LiDAR for 360-degree spatial awareness, tactile sensors mimicking human touch, and vision systems with multiple cameras. These sensors feed real-time data to onboard computers processing millions of data points per second.

Bipedal Locomotion Technology

Walking on two legs requires constant balance adjustments. Humanoids use the Zero Moment Point (ZMP) principle—a mathematical model that calculates the optimal center of gravity to maintain stability. This technology, combined with hydraulic or electric actuators, enables robots to walk, run, and even recover from stumbles.

Artificial Intelligence Integration

Modern humanoids leverage machine learning and neural networks to improve performance continuously. Tesla's Optimus Gen 2 learns from massive datasets collected across its fleet, while Figure AI's robots use foundation models to understand natural language commands and adapt to new tasks without extensive reprogramming.

Real-World Applications Transforming American Industries

Manufacturing and Automotive Production

The automotive sector is witnessing a humanoid revolution. BMW's Spartanburg plant is deploying Figure AI robots for complex assembly tasks, while Mercedes-Benz collaborates with Apptronik's Apollo for heavy-duty manufacturing operations. These robots handle tasks ranging from installing car seats to quality inspections—work requiring dexterity and precision that traditional robots struggle to achieve.

Warehousing and Logistics

With e-commerce demand skyrocketing, American logistics companies face unprecedented pressure. Agility Robotics' Digit handles this challenge by autonomously moving totes in Amazon's fulfillment centers, working 12-hour shifts and navigating complex warehouse layouts. The robot's ability to pick, transport, and place packages reduces human strain while boosting operational efficiency.

Healthcare and Eldercare

As America's population ages, humanoid robots offer solutions for healthcare staffing shortages. While still in early deployment, robots assist with patient mobility, medication delivery, and routine monitoring tasks. Their gentle touch sensors and adaptive grip prevent accidents while providing consistent care.

Hazardous Environment Operations

Humanoids excel where human safety is compromised. From nuclear facility inspections to disaster response scenarios, these robots venture into environments too dangerous for people. Their human-like form allows them to operate equipment designed for human hands and navigate spaces built for bipedal movement.

Leading American Players in Humanoid Robotics

The United States hosts some of the world's most innovative humanoid robotics companies, each pursuing unique approaches to commercial viability:

- Tesla (Optimus Gen 2): Leveraging automotive AI expertise, priced around $30,000 with plans for mass production by 2026

- Boston Dynamics (Electric Atlas): Emphasizing unmatched agility and dynamic movement for industrial inspection

- Agility Robotics (Digit): Focusing on practical logistics applications with proven warehouse deployments

- Figure AI (Figure 02): Targeting manufacturing with advanced manipulation and natural language processing

- Apptronik (Apollo): Partnering with major automakers for heavy-duty industrial operations

Challenges and the Path Forward

Despite rapid progress, humanoid robotics faces four critical challenges before achieving widespread adoption:

Safety Certification

Current regulations don't adequately address autonomous humanoids operating alongside people. New ISO standards are under development, but until certification pathways are established, large-scale deployment remains limited to controlled environments.

Battery Life and Uptime

Most humanoids operate only 2-4 hours per charge—far short of an 8-hour shift. Companies are developing swappable battery systems and fast-charging infrastructure, but sustained uptime remains the primary barrier to ROI.

Dexterity Limitations

Human hands possess 20-27 degrees of freedom; most robotic hands fall short. While adequate for tote handling and simple grasping, complex manipulation tasks requiring in-hand rotation and fine motor control remain challenging.

Cost Reduction

With current prototypes costing $150,000-$500,000, humanoids must reach $20,000-$50,000 price points to compete with human labor economically. This requires breakthroughs in manufacturing scale and component standardization.

Frequently Asked Questions About Humanoid Robots

How much do humanoid robots cost in 2025?

Current commercial humanoid robots range from $30,000 (Tesla Optimus projected price) to over $400,000 for advanced research platforms. As manufacturing scales and technology matures, experts predict prices will drop to $20,000-$50,000 within 5-7 years, making them economically viable for broader industrial adoption.

Will humanoid robots replace human workers?

Humanoid robots are designed to augment, not replace, human workers. They handle repetitive, physically demanding, or hazardous tasks, allowing humans to focus on roles requiring creativity, complex problem-solving, and emotional intelligence. The goal is human-robot collaboration, not substitution.

What industries will benefit most from humanoid robots?

Manufacturing, warehousing, logistics, and automotive sectors are leading early adoption. Healthcare, retail, hospitality, and construction will follow as technology matures. Any industry with labor shortages, safety concerns, or physically demanding tasks represents a potential application.

Are humanoid robots safe to work alongside humans?

Current humanoids incorporate multiple safety layers including force-limited actuators, proximity sensors, emergency stop systems, and compliance controls. However, most operate in semi-segregated areas until new ISO safety standards are finalized and regulatory frameworks are established for fully fenceless collaboration.

When will humanoid robots become mainstream in American workplaces?

Industry experts predict limited commercial deployments will expand significantly between 2025-2027, with broader mainstream adoption occurring by 2030-2035. The timeline depends on solving safety certification, battery life, dexterity, and cost challenges—the four critical bridges to cross before scaling from pilots to production.

The American Advantage in Humanoid Robotics

The United States holds a unique position in the global humanoid robotics race. While China pursues scale through rapid iteration and supplier ecosystems, American companies emphasize vertical integration, proprietary technology stacks, and safety-first design philosophies. This approach prioritizes long-term reliability and certifiable performance—qualities essential for brownfield deployment in regulated industries.

Major American corporations are voting with their checkbooks: Amazon, BMW, Mercedes-Benz, and others are committing billions to humanoid partnerships. Government support through initiatives like DARPA's robotics programs and NSF research grants further accelerates innovation. The convergence of AI breakthroughs, declining component costs, and pressing labor shortages creates the perfect storm for humanoid robotics to transition from research labs to factory floors.

As McKinsey's recent analysis emphasizes, the gap between demonstration and deployment is narrowing. Companies that prepare now—understanding use cases, piloting strategically, and building change management capabilities—will capture first-mover advantages when humanoid robots cross the chasm from concept to commercial reality.

Stay ahead of the robotics revolution! Share this comprehensive guide with industry colleagues and decision-makers who need to understand how humanoid robots are transforming American manufacturing and logistics. The future of work is being written today—be part of the conversation.