Tennessee Explosives Plants: Safety, Industry Impact & Recent Tragic Events

Tennessee Explosives Plants: Safety, Industry Impact & Recent Tragic Events

Table of Contents

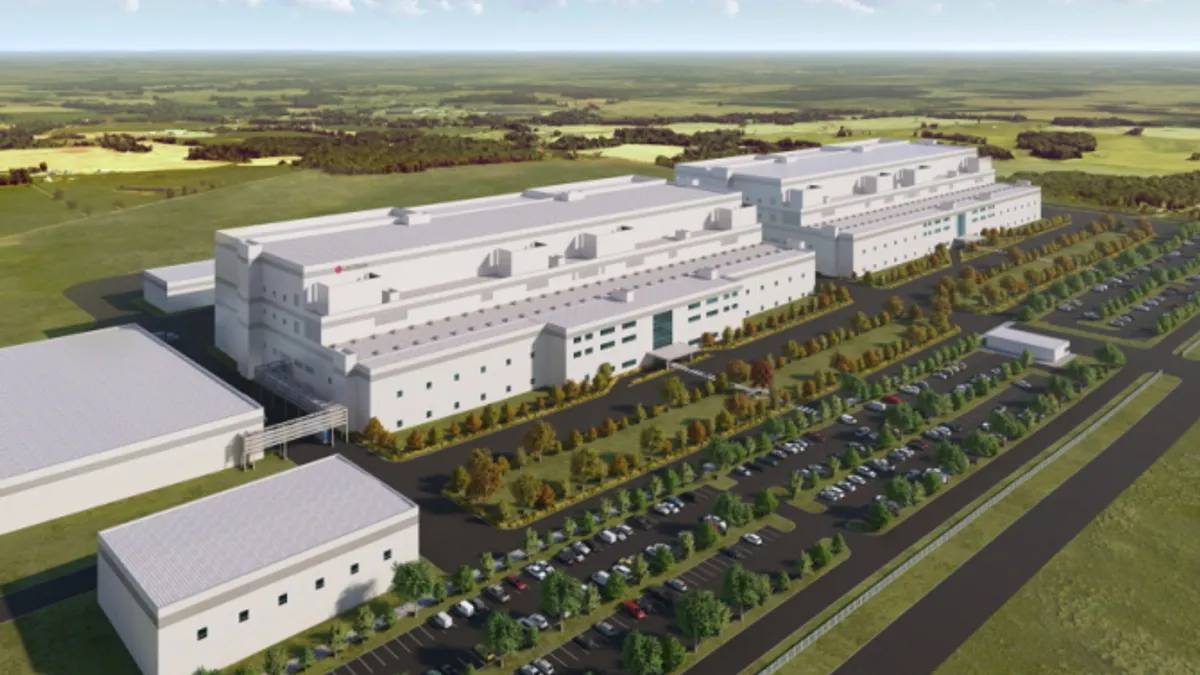

Tennessee has established itself as a significant hub for explosives manufacturing and munitions production, serving both military and civilian sectors. The state's strategic location, skilled workforce, and business-friendly environment have attracted numerous companies specializing in explosive materials, military ordnance, and related technologies. However, recent tragic events have highlighted the inherent dangers and critical importance of safety protocols in this high-risk industry.

Overview of Tennessee's Explosives Industry

The explosives manufacturing sector in Tennessee encompasses a diverse range of operations, from military munitions production to commercial explosives for mining and demolition. Companies like Accurate Energetic Systems have operated in the state for years, providing specialized explosive devices and energetic materials for defense contractors, aerospace applications, and industrial use.

Tennessee's explosives industry benefits from several key advantages:

- Strategic Location: Central location provides efficient transportation access to major markets

- Skilled Workforce: Experienced technicians and engineers with specialized knowledge

- Regulatory Environment: State support for manufacturing while maintaining federal safety standards

- Infrastructure: Established supply chains and support services for hazardous materials handling

Safety Protocols and Regulations

Explosives manufacturing facilities operate under stringent federal regulations administered by multiple agencies, including the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF), the Occupational Safety and Health Administration (OSHA), and the Department of Transportation (DOT). These regulations cover every aspect of operations from storage and handling to transportation and disposal.

Key Safety Requirements Include:

- Facility Design: Blast-resistant construction with proper separation distances

- Personnel Training: Comprehensive safety training and certification programs

- Emergency Protocols: Detailed evacuation and response procedures

- Equipment Maintenance: Regular inspection and maintenance of all machinery

- Environmental Controls: Temperature, humidity, and static electricity management

Recent Tragic Incident in McEwen

On October 10, 2025, a devastating explosion occurred at Accurate Energetic Systems in McEwen, Tennessee, approximately 50 miles west of Nashville. The blast, which happened around 7:45 AM, completely destroyed one building and resulted in the presumed death of 18 workers who were unaccounted for after extensive search efforts.

Humphreys County Sheriff Chris Davis described the incident as "one of the most devastating situations" he had encountered in his career. The explosion was so powerful that it shook homes over 10 miles away, with residents initially thinking it was an earthquake or tornado. Debris was scattered across a half-mile radius from the blast site.

Emergency Response Efforts

More than 300 state and local first responders participated in search and recovery operations. Specialized teams from the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) deployed certified explosives specialists and bomb technicians to secure the site and safely dispose of remaining hazardous materials.

Economic Impact on Local Communities

Explosives manufacturing facilities often serve as significant employers in rural Tennessee communities. These plants typically offer well-paying jobs that require specialized skills, contributing substantially to local economies. The loss of such facilities can have lasting economic impacts on surrounding communities, affecting not only direct employees but also local businesses and suppliers.

Community Considerations:

- Employment: High-paying technical positions for local residents

- Tax Revenue: Significant property and business tax contributions

- Supply Chain: Support for local contractors and service providers

- Infrastructure: Investment in local roads, utilities, and services

Enhanced Safety Measures and Future Outlook

Following major incidents, the explosives manufacturing industry typically implements enhanced safety measures and reviews existing protocols. These improvements may include advanced monitoring systems, improved facility design standards, and enhanced emergency response procedures.

Potential Industry Improvements:

- Technology Integration: Advanced sensors and monitoring systems

- Training Enhancement: More frequent and comprehensive safety training

- Facility Upgrades: Improved blast containment and separation measures

- Emergency Preparedness: Enhanced coordination with local first responders

Frequently Asked Questions

What types of explosives are manufactured in Tennessee?

Tennessee facilities produce various types of explosives including military munitions, commercial explosives for mining and demolition, aerospace propellants, and specialized energetic devices for defense applications.

How are explosives plants regulated for safety?

Explosives manufacturing facilities must comply with federal regulations from multiple agencies including ATF, OSHA, and DOT. These regulations cover facility design, storage, handling procedures, personnel training, and emergency response protocols.

What should residents near explosives facilities know about safety?

Residents should be aware of emergency evacuation routes, understand warning systems, and know how to report suspicious debris. Most facilities maintain buffer zones and coordinate with local emergency services for public safety.

How do explosives plants impact local economies?

These facilities typically provide high-paying technical jobs, contribute significant tax revenue, and support local supply chains. They often represent major employers in rural communities where such opportunities may be limited.

What happens during an explosives plant emergency?

Emergency response involves immediate evacuation, specialized hazmat teams, explosives disposal experts, and coordination between multiple agencies. Recovery operations can take days or weeks depending on the incident severity.

The explosives manufacturing industry in Tennessee continues to play a vital role in national defense and commercial applications. While recent tragic events highlight the inherent risks involved, ongoing improvements in safety technology, training, and regulatory oversight aim to protect both workers and surrounding communities. The industry's future depends on maintaining the highest safety standards while supporting the economic needs of rural Tennessee communities that rely on these specialized manufacturing operations.